Seal Manufacturing

-

Machined seals

-

Flat-cut gaskets

-

Vulcanized Seals

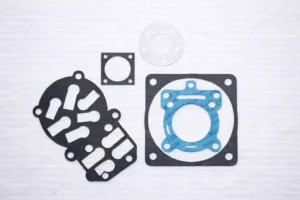

Machined seals

Machined seals represent a modern and highly flexible solution for demanding industrial applications where standard off-the-shelf seals are no longer sufficient. By using CNC machining, we manufacture seals precisely to customer specifications, based on technical drawings, samples, or specific application requirements. This production method allows for fast adaptation of dimensions, profiles, and functional characteristics without the need for costly tooling, making it particularly suitable for prototypes, small to medium series, or urgent deliveries.

We machine seals from a wide range of high-quality materials, including polyurethane (PU), PTFE and PTFE compounds, NBR, EPDM, H-NBR, VMQ, FKM (Viton®), POM, and other engineering polymers. Material selection is based on operating conditions such as pressure, temperature, speed, chemical resistance, and the type of media involved. Drawing on many years of experience, we support our customers in selecting the optimal material and seal geometry to ensure long service life, reliable sealing performance, and reduced maintenance costs.

Our custom-made approach allows us to fully adapt to customer needs — from special seal profiles for hydraulic and pneumatic systems to individual solutions for specific machinery, refurbishment of older equipment, or optimization of existing sealing systems. With fast response times, technical expertise, and high manufacturing precision, we are a reliable partner in the development and supply of sealing solutions that perform even under the most demanding operating conditions.

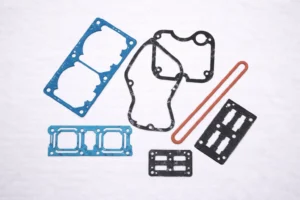

Flat-cut gaskets

In addition to machined seals, we also manufacture flat-cut gaskets, tailored to a wide range of shapes and application requirements. The gaskets are cut from high-quality materials such as NBR rubber, EPDM, and other elastomers, as well as from compressed fiber gasket materials and various composite materials designed to withstand different mechanical, thermal, and chemical loads. Based on the customer’s requirements, we assist in selecting the appropriate material, thickness, and geometry to ensure reliable sealing performance and long service life.

Flat-cut gaskets are suitable for both industrial applications—including mechanical engineering, energy systems, plumbing installations, and maintenance—and domestic use, where special dimensions or non-standard shapes are often required. Custom manufacturing allows for quick adaptation to specific needs, refurbishment of existing sealing solutions, or replacement of hard-to-source original parts, while ensuring high accuracy, repeatability, and dependable performance in real-world applications.

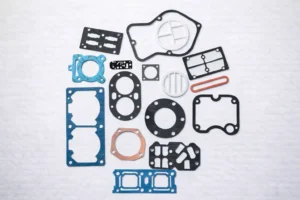

Vulcanized Seals

In addition to machining and cutting seals, we also manufacture seals and technical rubber components using the vulcanization process in molds. We work with high-quality raw rubber compounds, FKM, and silicone, available in various hardness grades and tailored to the specific requirements of each application. Based on the customer’s drawings or technical documentation, we first design and produce the required tooling, which is manufactured entirely in-house using modern CNC machining. This allows us to maintain full control over quality, ensure short lead times, and remain highly flexible even for more demanding projects.

The final products are then vulcanized in our in-house manufactured molds. These products are not limited to seals alone but also include other technical rubber components for industrial and specialized applications. This integrated approach—from tool development to the finished product—ensures high repeatability, stable mechanical properties, and reliable performance even under demanding operating conditions. In this way, we provide our customers with a complete solution for series production or the development of custom-made rubber components.